Gas Compression Engines:

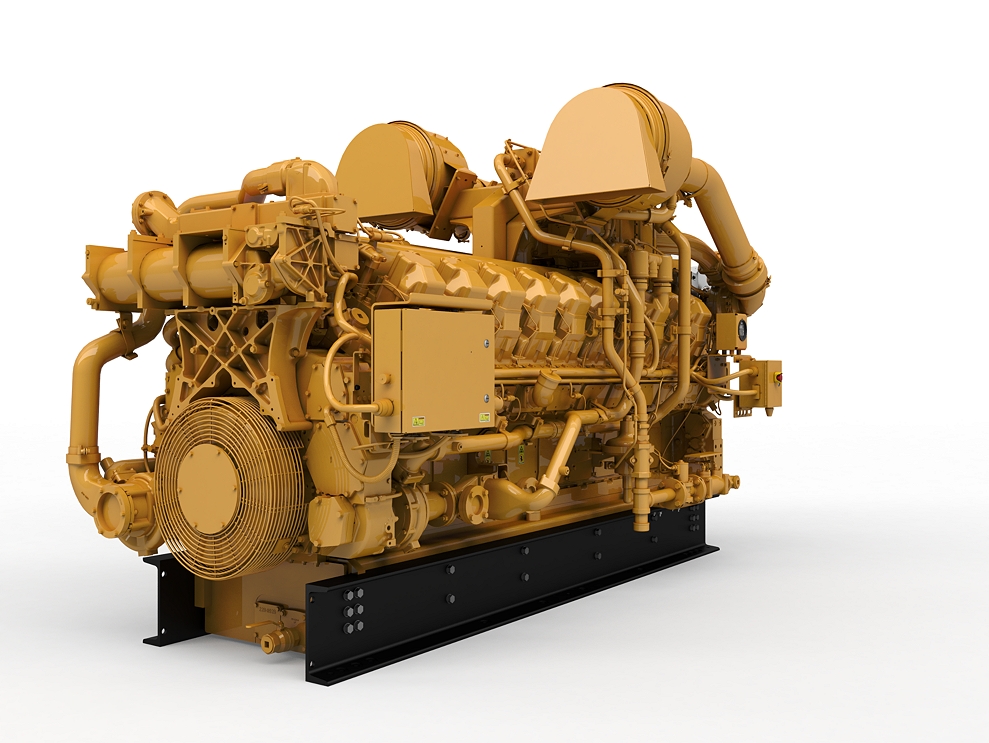

G3520J Gas Compression Engine

Contact Us About This Product

Click a link to download the document:

- Minimum Rating

- 1725 BHP

- Emissions

- U.S. EPA Spark Ignited Stationary NSPS emissions for 2010

- Bore

- 6.7 in

- Rotation from Flywheel End

- Counterclockwise

The line of G3520J engines brings versatility, uptime, and low operating cost to your gas compression operation. They deliver the lowest engine-out emissions in the industry without sacrificing performance. Ideal applications for G3520J engines include primary gathering, central gathering, and gas processing plants.

Product Specs

-

Engine Specifications

- Minimum Rating

- 1725BHP

- Emissions

- U.S. EPA Spark Ignited Stationary NSPS emissions for 2010

- Bore

- 6.7in

- Rotation from Flywheel End

- Counterclockwise

- Stroke

- 7.5in

- Combustion

- Lean Burn

- Oil Change Interval

- 2000 hrs

-

Capacity for Liquids

- Lube Oil System - Refill

- 143gal (US)

-

Governor and Protection

- Governor and Protection

- Electronic (ADEM™ A3)

Equipment

-

- Air Inlet System

-

- Axial Flow Air cleaner

- Single element canister type with service indicator

-

- Cooling System

-

- Two-stage charge air cooling: First stage - JW + OC + 1st stage AC / Second stage - 2nd stage AC

- Jacket water and aftercooler thermostats

-

- Exhaust System

-

- Water-cooled exhaust manifolds

- Dry turbocharger housings

- Water-cooled exhaust elbow

-

- Flywheels And Flywheel Housings

-

- SAE No. 21 flywheel

- SAE No. 00 flywheel housing

- SAE standard rotation

-

- Fuel System

-

- 7-40 psig gas supply

- Electronic fuel metering valve

- Gas pressure regulator

- Gas shutoff valve

-

- Instrumentation

-

- Remote-mounted Advisor control panel

- Product Link cellular radio

-

- Lubrication System

-

- Crankcase breather — top mounted

- Oil cooler

- Oil filter — RH

- Oil pan — 143 gal

- Oil sampling valve

- Turbo oil accumulator

-

- Mounting System

-

- Rails

-

- Power Take-offs

-

- Front housing — two-sided

- Front lower LH accessory drive

-

- General

-

- Paint — Cat yellow

- Crankshaft vibration damper and guard

-

- Air Inlet System

-

- Round air inlet adaptors

- Rain shield

-

- Charging System

-

- CSA alternator (24V,65A)

-

- Cooling System

-

- Jacket water inlet flange-hose connection

-

- Exhaust System

-

- Flexible fittings

- Flanges

- Elbow

-

- Fuel System

-

- Fuel filter

-

- Instrumentation

-

- LAN adapter

- 15',40',90',140' Product Link extension harness

- 20',30',50',100' interconnect harness

-

- Lubrication System

-

- Lubricating oil

- Oil bypass filter

- Air prelube pump

- Oil pan drain

-

- Power Take-offs

-

- Front stub shaft

- Crankshaft pulley

-

- Starting System

-

- Air pressure regulator

- 90 psi starter

- 150 psi starter

- Jacket water heater

-

- General

-

- Special paint

- Crankshaft vibration double damper

- Explosion relief valves

-

- Eu Certification

-

- EEC DOI certification